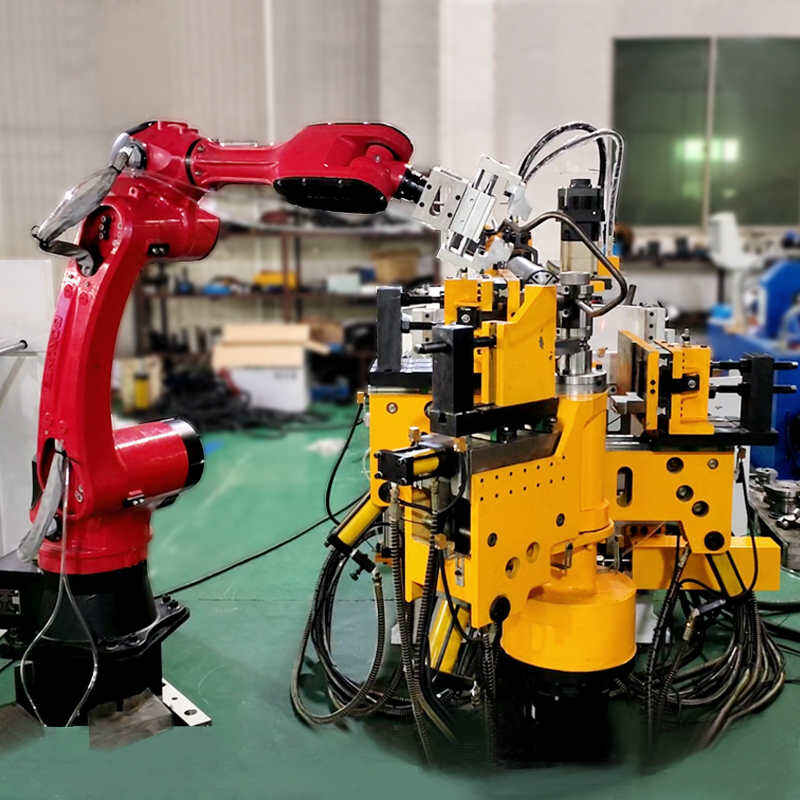

کل سناریوی خم شدن لولهها کاملاً نسبت به روزگار قدیم تغییر کرده است، زمانی که لولهها به صورت دستی خم میشدند. در گذشته، ساختن آنها به شکل خطی فرآیندی طولانی و سخت بود. بائو رویی از روش مدرنی برای خم کردن لولهها استفاده میکند که همچنین جالب است: فناوری CNC. این روش خم شدن لولهها را بسیار آسانتر و سریعتر میکند و همچنین با سطح عالی از جزئیات انجام میدهد.

این ماشین از فناوری گیوه کننده لوله فولاد راستالگو استفاده میکند که به ماشینها کمک میکند تا لولهها را به شکلها و منحنیهای مختلف خم کنند. این ماشین قادر است تقریباً هر طراحیای که طراحان زیادی زمان برای انجام آن صرف میکنند را با دقت فوق العاده انجام دهد. به طور کلی، این بدان معناست که تمام قطعات تولید شده با این فناوری دقیقاً یکسان خواهند بود، یعنی دارای یکنواختی هستند. برنامههای کامپیوتری فرآیند خم شدن را روی ماشینها کنترل میکنند و مطمئن میشوند که هر خم دقیق باشد. این موضوع عالی است زیرا احتمال ارتکاب خطا که ممکن است در خم کردن دستی لولهها رخ دهد، کاهش مییابد.

با اینکه اقتصادی و کارآمد هستند، ماشینهای خم شدن لوله CNC در دقت عملکرد خود برتری دارند. به این دلیل، آنها قادرند لولهها را با دقت خم کرده و همچنین در زمان کمتری مدیریت کنند. یکی از مزایای عالی فناوری CNC این است که نیازی به نیروی انسانی برای خم شدن دستی نیست. این موضوع به فرآیندهای سریعتر و سادهتر خم شدن برای تمام طرفها اجازه میدهد. این ماشینها میتوانند لولههایی با اندازه یکسان تولید کنند که برای جمعآوری و ساخت و ساز کاربردهای بسیاری دارد.

یکی از مزایای برجسته فناوری خم شدن سیم CNC، توانایی ایجاد خمشهای ویژه به راحتی است. در حقیقت، اگر مشتری میخواهد لوگویی در خمشش وجود داشته باشد، ماشین CNC میتواند برای نقره کردن طراحی مورد نظر تنظیم شود. ماشینهایی که این نرمافزار را شامل میشوند قادر به خواندن طرحهای طراحی شده روی کامپیوتر هستند. این موضوع به ماشین اجازه میدهد تا خمشهای ویژه بر اساس درخواست مشتری مشخص را انجام دهد.

فناوری CNC بائو روی برای تولید سریع و پایدار اندازه لوله این بائو روی ماشین خمکننده لوله فولاد ریز اطمینان میدهد که مشتریان میتوانند سفارشات خود را قبل از یک مهلت مشخص دریافت کنند و نباید نگران باشند فقط به دلیل وجود رکوردهای ناآشنا تحت عنوان طلا. و هنگامی که تولید کارآمد باشد، شرکتها در زمان کمتر لولههای بیشتری تولید میکنند و بنابراین بیشتر درآمد بدست میآورند. فرآیند خودکار نیز به این معناست که لولههای تولید شده دارای کیفیت بالاتر و هماهنگی بیشتری هستند که به نوبه خود به مشتریان هر بار آنچه پرداخت کردهاند را تحویل میدهد.

چرا که حقیقت این است که فناوری خم شدن تُب توسط CNC واقعاً در جایگاه مناسبی قرار دارد زمانی که به ساخت تُبها میپردازیم. در حالی که این فناوری ادامه دادن به رشد و پیشرفت دارد، بدون شک میتوانیم پیشرفتهای بیشتری در کاربردهای اضافی و روشهای بهتر تولید تُب برای صنایع مختلف انتظار داشته باشیم. این نوآوری مستمر جالب است، چون راه را برای پتانسیلهای جدید در طراحی و تولید تُب هموار میکند.

به یاد داشته باشید، فناوری خم شدن تُب CNC جایگزین نیروی انسانی با رباتها نیست. اینطور نیست، بلکه این یک ابزار است که برای ساخت محصول عالی که نیازهای مشتریان را برآورده میکند، مورد استفاده قرار میگیرد. این فناوری Bao Rui cnc bender امکان میدهد تا ما به عنوان تولیدکننده تُب، بهترین کار خود را انجام دهیم و رشد کنیم و بنابراین موفقیت کسب و کار را برای سالهای آینده تضمین کنیم.

استفاده از روش بازرسی منظم برای تضمین عملکرد بهینه و افزایش عمر منابع نور پروژکتورها ما، و کاهش دوام زمان توقف. تولید چراغ لیزر تمرکز بر ساخت روابط بلندمدت با ارائه راهحلهای سفارشی شده برای نیازهای شما است که رشد هر دو طرف را تشویق میکند و نوآوری را تقویت میکند. ما گواهینامه سیستم کیفیت ISO9001، گواهینامه CE و گواهینامه SGS را دریافت کردهایم. قبل از ارسال، ما تجهیزات را آزمایش میکنیم، ویدئوی بررسی یا فیلم زنده CNC لوله خمش تأمین میکنیم و ضمانت یک ساله ارائه میدهیم. فناوری پیشرفته شرکت ما، تجهیزات پیشرفته و مدیریت مناسب، به آن اجازه داده است که حاشیه رقابتی خود را در بازارهای بینالمللی و داخلی حفظ کند. تمام محصولات ما در سراسر کشور پوشش دارند و به کشورهای اروپا، آمریکا و جنوب شرق آسیا صادر شدهاند و توسط مشتریان خوب پذیرفته شدهاند.

ما دامنه وسیعی از مسیرهای لوژستیکی را ارائه میدهیم، مانند حمل و نقل زمینی، حمل و نقل دریایی، حمل و نقل هوایی، و غیره. ما طیف گستردهای از گزینههای حمل و نقل را ارائه میدهیم تا مطمئن شویم کالاها به مقصد خود تحویل داده میشوند. در حال حاضر، ما خدمات به یک شرکت Cnc tube bending در سراسر جهان ارائه میدهیم و به بیش از 60 کشور صادرات انجام میدهیم.

شرکت Cnc tube bending ساختارهای کارخانهای مدرن، خطوط تولید حرفهای و تجهیزات آزمایشی، همچنین گروهی از طراحان طراحی حرفهای و فنیدانان دارد. این شرکت بیش از 20 سال در این صنعت فعالیت کرده است و متخصص در تولید طیف کاملی از ماشینهای خمش لوله CNC هیدرولیکی، بریدن لوله، بریدن آلومینیوم، ماشین چسباندن گوشه، ماشین پیکربندی دنده و محصولات دیگر است. ما چندین ماشین سفارشی و فردیسازی شده را برای برآورده کردن نیازهای سفارش شما ارائه میدهیم.

ما شریک قابل اعتماد و مورد اعتماد در صنعت پردازش لوله و پروفیل هستیم.