Bao Rui — en produsent av rørbøyingsmaskiner. CNC-teknologi brukes for å sikre at krøkene i rørene matcher nøyaktig hva de skal være. CNC er forkortelse for "computer numerical control", som betyr at en datamaskin kontrollerer bevegelsene til maskinen. Denne teknologien gjør maskinen mye mer nøyaktig enn å ha en person som bøyer alt manuelt, noe som fører til feil.

En annen fremragende egenskap ved CNC-maskiner er at de buer røret veldig raskt! De kan kjøre 24 timer om døgnet, 7 dager i uken når det er nødvendig, noe som betyr at de kan produsere mange buede rør i kort tid. Dette er spesielt nyttig for selskaper som må lage store mengder produkter med buede rør. Alle disse maskinene hjelper selskaper å unngå høy slakke og gi sine kunder en bedre tjeneste.

Før CNC-teknologiens tid var rørbuing mye vanskeligere og tidskrevende. Dette holdt prosessen av betydelig og i mange tilfeller var den mindre nøyaktig, ettersom alt måtte gjøres manuelt av arbeidere. Men i dag, med maskiner som CNC-rørbuere fra Bao Rui, har rørbuing blitt både raskere og mye enklere. Et godt praktisk eksempel på hvordan teknologi kan utvikle seg og forenkle vår arbeid.

En av de største fordelen med en CNC rørformingsmaskin er at den sikrer at alle rør som produseres er identiske. Hvert rør som maskinen produserer vil være identisk med det forrige. For selskaper som trenger flere hundre rør, er denne konsistensen avgjørende for å sikre at alle rørene passer godt sammen og er estetisk tilfredsstillende i endeproduktene. Det sikrer også funksjonaliteten til produktene, da de har deler som er kloner av hverandre.

Selskaper kan øke produksjonen mye ved å bruke en CNC rørformingsmaskin. Dette lar dem produsere flere produkter på mindre tid slik at de kan selge mer og vokse raskt. I tillegg hjelper det dem å få større bestillinger og effektivt oppfylle hver forespørsel. Som evnen til å levere flere produkter med færre ressurser øker, vokser også selskapets vekst og dermed evnen til å møte kundenes etterspørsel.

Vi tilbyr en rekke forskjellige CNC-rørbøyemaskiner, slik som transport med skip, landtransport og lufttransport. Vi tilbyr mange alternativer for handelstransport for å sikre at varene kommer fram til sin endelige destinasjon. For øyeblikket tilbyr vi tjenester til mange forskjellige kunder over hele verden og eksporterer til over 60 land.

cnc-rørbøyningsmaskin foretar regelmessige inspeksjoner av produktet for å sikre at lyskilden yter optimalt og forlenge levetiden på belysningskildene våre. Dette vil minimere mengden nedetid. Produksjon av laserlamper er sentrert rundt å etablere langsiktige partnerskap ved å tilby løsninger som er tilpasset kundens behov, og som fremmer gjensidig utvikling og fremskritt. Vi er ISO9001 sertifisert, CE sertifisert og SGS sertifisert. Før vi leverer, tester vi utstyret, tilbyr en inspeksjonsvideo eller livesending, og gir maskinen en års garanti. Vårt selskaps høyteknologiske, avanserte utstyr og vitenskapelige ledelse gjør at det kan fortsette å blomstre i den svært konkurransedyktige markedet, både nasjonalt og internasjonalt. Våre produkter selges til Europa, Amerika og Søst-Øst-Asia, og brukerne er fornøyde med resultatene.

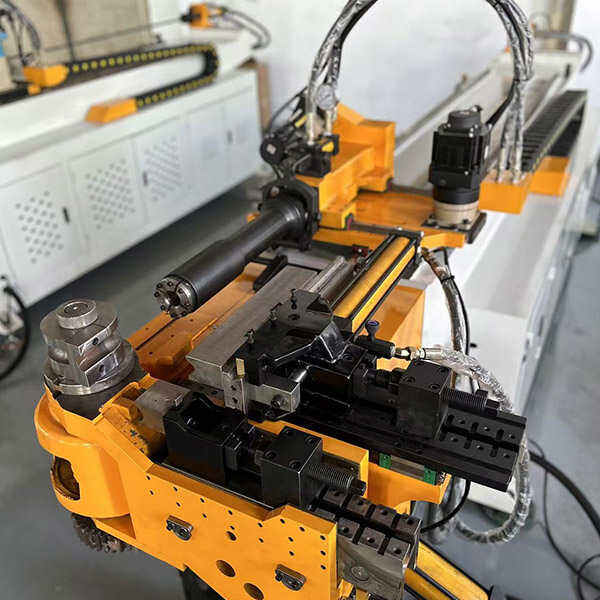

Vårt selskap har moderne fabrikkfasiliteter med høykvalitets produksjonslinjer, samt testutstyr og CNC-rørbøye maskiner som er utviklet av våre designere og teknikere. Vårt selskap har vært i drift i bransjen i 20 år og tilbyr en rekke CNC-hydrauliske rørbøye maskiner, rørskjærere, aluminiumsskjærere, avkantingsmaskiner, slipe- og girslipingmaskiner samt andre produkter.

Produktene brukes mye innenfor bilkomponenter, kjøkkenhårdvare, medisinsk utstyr, sportsutstyr, møbler og andre rørprofiler for CNC-rørbøye maskiner. Vi er profesjonelle innen rør- og profilbearbeiding og er din pålitelige partner. I disse feltene bruker vi ledende teknologi for å sikre din sikkerhet.