В условиях трансформации автомобильной промышленности, стремящейся к высокой точности, эффективности и экологичному производству, холодные пилы становятся предпочтительным оборудованием для обработки ключевых компонентов, таких как трубы каркасов сидений и выхлопные трубы, благодаря своим уникальным преимуществам. Их основная ценность точно соответствует ключевым потребностям отрасли.

Высокая точность, исключающая необходимость вторичной обработки

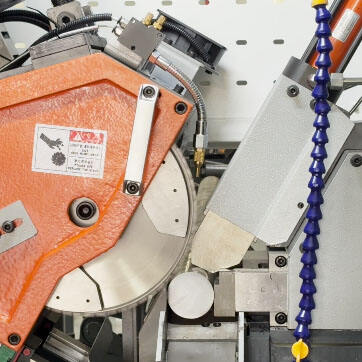

Холодная пила использует технологию холодного резания, при которой в процессе резки выделяется мало тепла, что предотвращает деформацию и изменения материала труб. Поверхность реза гладкая, без заусенцев и имеет высокую перпендикулярность. Последующая шлифовка не требуется, возможна прямая сборка, что с самого начала обеспечивает точную посадку и герметичность выхлопной трубы, значительно снижая риск переделок.

Высокая адаптация, значительные преимущества в снижении затрат

Холодные пилы обеспечивают значительно более высокую эффективность резки по сравнению с традиционным оборудованием, а их пильные диски можно многократно затачивать, продлевая срок службы и эффективно контролируя расходы на материалы. Они также совместимы с различными материалами, такими как алюминиевые сплавы, нержавеющая сталь и жаропрочные сплавы, что позволяет одной машине удовлетворять потребности обработки множества деталей и повышает гибкость производственной линии.

Интеллектуальное и экологически чистое решение, соответствующее современным отраслевым тенденциям

Современные холодные пилы оснащены интеллектуальными системами управления, поддерживающими хранение параметров и удаленный мониторинг. Они просты в эксплуатации и обучении, что снижает затраты на рабочую силу. Процесс резки проходит без искр, с низким уровнем шума и без образования пыли, соответствует требованиям к окружающей среде и безопасности на производстве. Кроме того, они обладают энергосберегающими характеристиками, отвечающими потребностям автомобильной отрасли в низкоуглеродной трансформации.

Благодаря своим основным преимуществам — «точность, высокая эффективность и экологичность» — холодная пила стала важным инструментом для обработки автомобильных деталей, обеспечивая качество продукции и оптимизацию производственной эффективности. Это важный выбор оборудования для предприятий, стремящихся противостоять отраслевой конкуренции.