I. Core Multifunctional Dimensions

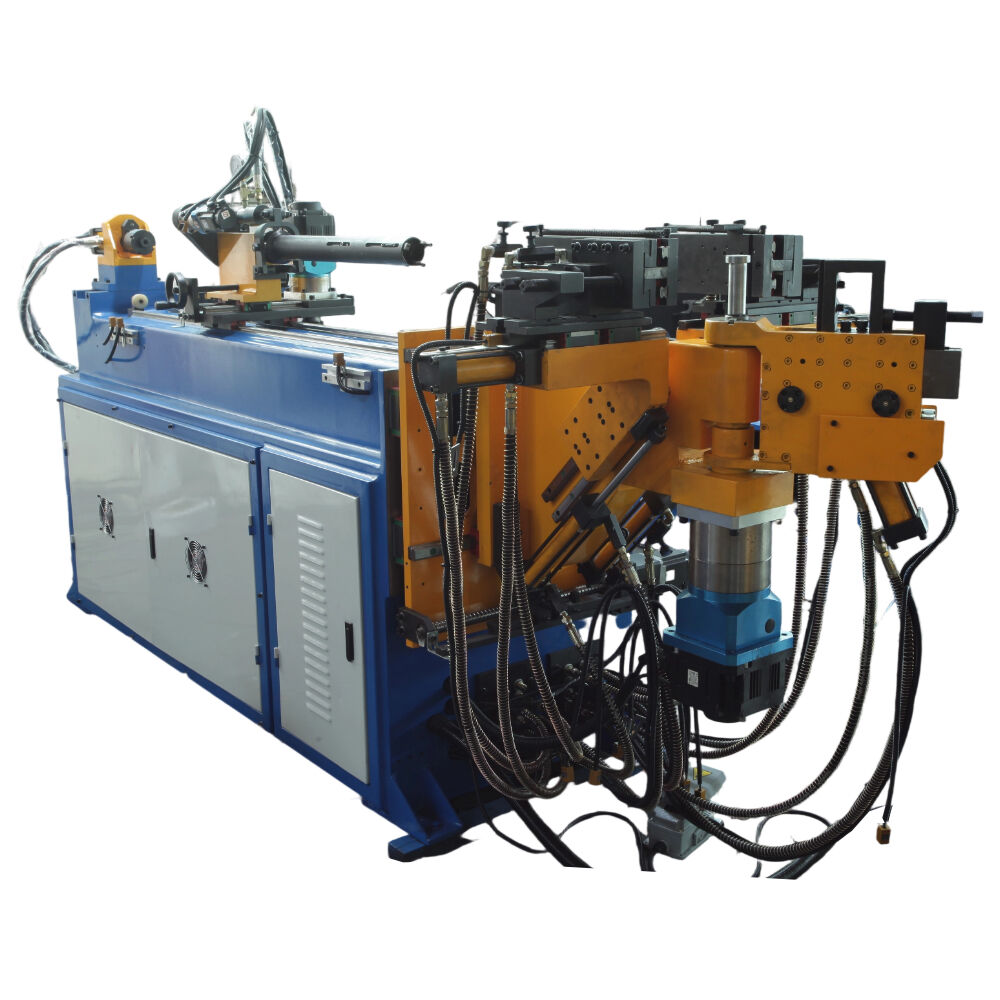

Multi-pipe compatibility: Processes metals (carbon steel/stainless steel/aluminum/copper), plastics (PVC/PE), etc., with pipe diameters ranging from Φ3-Φ219mm and wall thicknesses from 0.5-10mm. No need to change the main unit; only the mold needs to be changed for switching.Multi-process integration: In addition to the core bending function, some high-end models integrate chamfering, deburring, necking/flaring, and drilling processes, achieving "one-time forming" and reducing subsequent equipment investment;Multi-bending modes: Supports fixed angles of 90°/180°, continuously adjustable angles from 0° to 180°, and 2D/3D bending (complex piping such as car seat frames and air conditioning pipes), meeting the needs of different product structures;Multi-volume adaptability: Through programming switching, it can achieve small-batch customization (such as sample processing), medium-batch production (100-500 pieces per day), and large-batch mass production (500+ pieces per day), adapting to order fluctuations;Multi-scenario adaptability: Fixed workshop workstations (CNC models), on-site construction (portable models), and foreign trade exports (global voltage + multi-language interface), one machine covers multiple usage scenarios.

II. Practical Application of Multifunctional Features

• Automotive Industry: The same machine can process seat frames, exhaust pipes, and air conditioning ducts (through mold switching and programming), adapting to the production of parts for different car models.

• Furniture Industry: It can also process table and chair frames (simple two-dimensional bending), sofa frames (complex multi-bend structures), and metal railings (continuous bending of long pipes).

• Building Materials Industry: It processes door and window frames, scaffolding pipes, and solar panel brackets, compatible with batch processing of different materials and pipe diameters.

• International Trade: The equipment supports CE/TS16949 certification, is globally voltage compatible, and features a multilingual operating interface, meeting the diverse processing needs of customers in different countries.

III. Core Selling Points for Foreign Trade Promotion

"One machine does the work of many": Reduces customer equipment procurement costs, minimizes workshop space requirements, and improves return on investment;Rapid changeover: Mold changeover time < 5 minutes, supports CAD drawing import, adaptable to small-batch, multi-variety orders (core needs of overseas SMEs);Full-scenario adaptability: Compatible with multiple materials, processes, and production volumes, requiring no additional equipment and reducing subsequent operating costs;Stable quality: Standardized configuration of core components (servo motors/molds), maintaining accuracy (±0.05° angular tolerance) under various operating conditions.