Pipe cutting is a fundamental process in industries such as machinery manufacturing, automotive parts, and building materials. Its quality directly determines the accuracy of subsequent processing, product performance, and service life. Unlike ordinary sheet metal cutting, pipe cutting, due to its hollow structure and circular/irregular cross-section characteristics, has specific requirements for cutting processes, equipment, and operations. The core focus is on three dimensions: precision control, efficiency adaptation, and safety compliance.

I. Precision Requirements: Stringent standards for both dimensions and cuts

Error control down to the micrometer level: Pipe cutting requires strict control of length tolerance (usually ±0.1-0.5mm), especially in precision applications such as automotive oil lines and aviation hydraulic lines, where length deviations can lead to assembly jams and sealing failures.The cut quality must be burr-free and deformation-free. Hollow pipe cutting is prone to burrs and edge collapse, requiring processes such as high-frequency vibrating blades and laser cutting to achieve a "burr-free cut." The inner wall smoothness Ra≤1.6μm should be maintained to prevent turbulence or impurity accumulation during fluid transport. In addition, high-temperature cutting should be avoided to prevent pipe end face oxidation and coarse grains, especially for materials such as stainless steel and copper alloys, as the oxide layer will affect the welding strength.

II. Efficiency Requirements: Adaptable to mass production and material characteristics

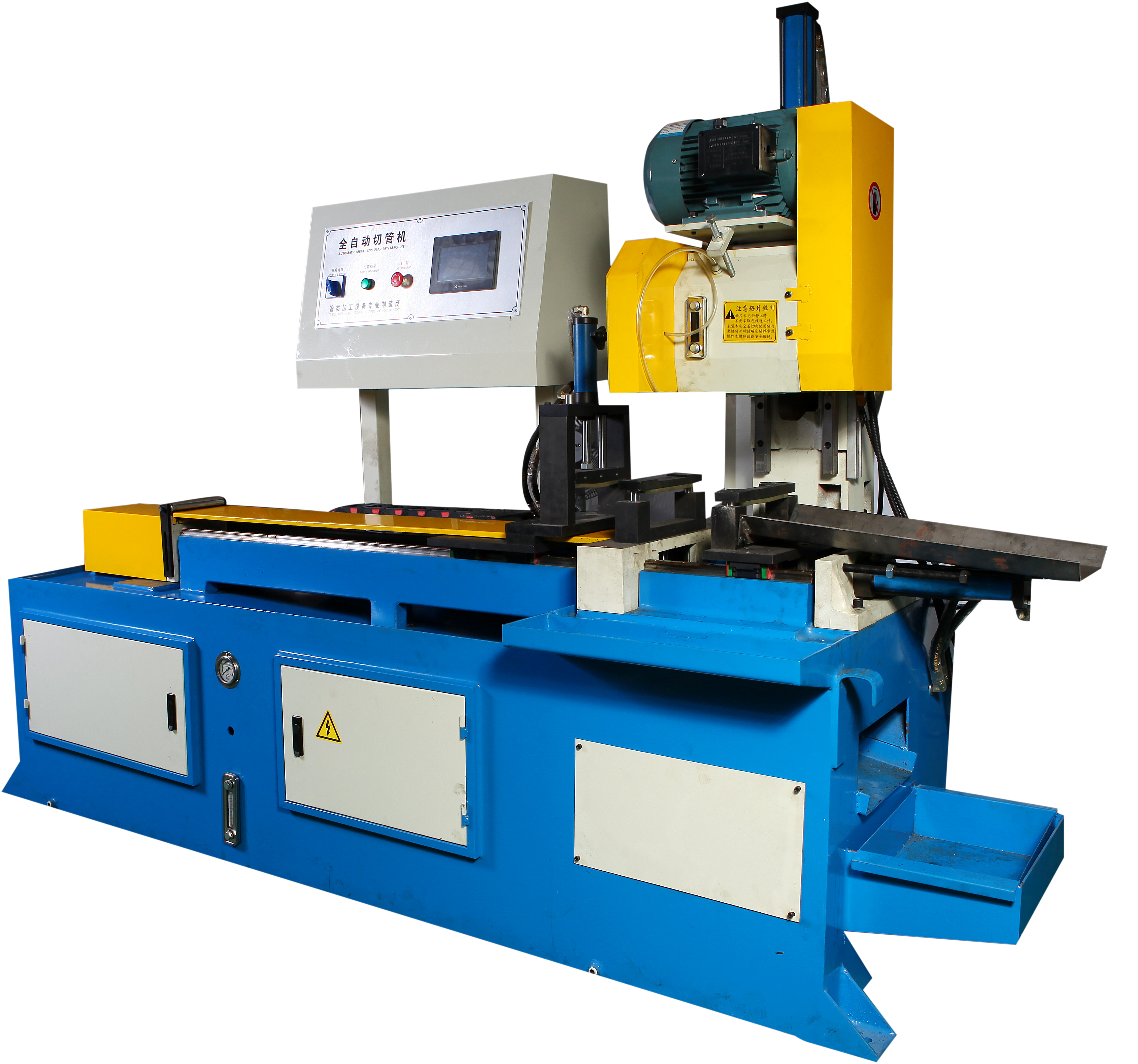

In industrial settings, the equipment must meet the requirements for continuous batch cutting. It must have automatic feeding, positioning, and unloading functions, and the cutting speed can reach 10-50m/min depending on the pipe diameter (10-200mm). At the same time, it must ensure long-term trouble-free operation (continuous operation ≥8 hours) and be compatible with the production line cycle time.

III. Safety and Compliance Requirements: Operating Procedures and Environmental Standards

Protective devices (such as laser safety glasses and anti-splash shields) must be provided during the cutting process to prevent injury from high-temperature sparks and debris; the electrical control system must have overload protection and emergency shutdown functions to avoid accidents caused by equipment failure; for high-pressure gas-assisted cutting (such as nitrogen for laser cutting), the pipeline must be sealed and leak-free.Dust and debris generated from metal cutting must be collected and treated by dust collection equipment to avoid air pollution; cutting fluid must be environmentally friendly and have recycling functions to reduce waste liquid discharge; noise must be controlled below 85dB to meet the environmental protection standards of industrial workshops.

The core requirements for pipe cutting are "adapting to the scenario, balancing accuracy and efficiency, and adhering to the bottom line of safety." As the requirements for pipe processing accuracy continue to increase in industries such as automobiles, new energy, and aerospace, cutting equipment is developing towards "intelligentization, high precision, and multi-material compatibility." Strictly following cutting requirements is a key prerequisite for ensuring product quality and improving production efficiency.