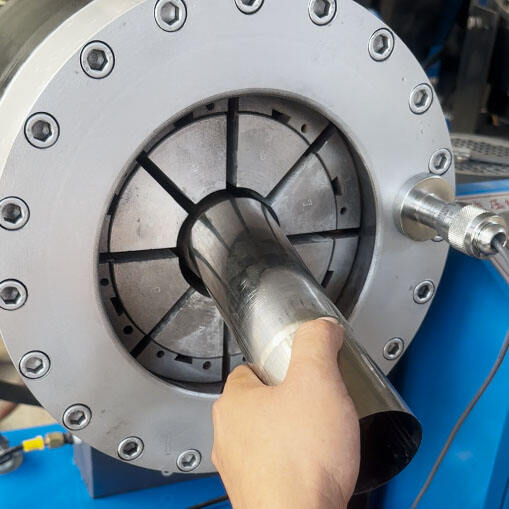

Tube shrinking machines are core equipment for processing metal tubular components such as car seats and exhaust pipes. With their advantages of precision and efficiency, they have become an essential tool for mass production. However, they also have certain limitations in application and need to be rationally selected based on the production scenario.

Core advantages

• High Precision: CNC control error ±0.01mm, meeting automotive parts assembly standards and improving the pass rate.

• High Efficiency: 10-30 pieces/minute continuous operation, replacing 3-5 workers and reducing batch production cycle time.

• Strong Adaptability: Compatible with carbon steel, aluminum alloy, and other materials, covering pipe diameters from φ5-φ100mm, suitable for various components.

• Low Loss: Loss rate ≤1%, cold/heat shrinking process ensures the mechanical properties of the pipe, meeting automotive safety requirements.

• Easy Operation: Touch screen + industry parameter library, workers can be trained quickly and put to work, reducing labor costs.

Application limitations

• High investment: A single unit costs between 100,000 and 500,000 RMB, placing a heavy initial investment burden on small and medium-sized enterprises.

• Difficult changeover: Custom molds and parameter adjustments require 1-4 hours, unsuitable for small-batch, multi-production.

• Strict pre-treatment: Requires removal of oil and rust from pipes, increasing production complexity.

• High maintenance costs: High maintenance costs for core components; troubleshooting relies on specialized technicians.

• Limited compatibility: High-strength alloys and thin-walled pipes are prone to cracking, requiring specialized processes.

When mass-producing standard pipe components, pipe shrinking machines offer significant efficiency advantages; for small-batch orders, semi-automatic equipment or outsourcing can be chosen. When purchasing, prioritize brands with quick mold changes and comprehensive after-sales service, and combine them with standardized pre-treatment and maintenance processes to maximize the value of the equipment.