Pipe cutting is a very important work in construction and building. It involves producing pipes that are apt in terms of their size and shape for fitting into a number of locations within the structure. It might seem trivial to cut pipes, but doing so requires special tools and techniques to ensure the most precise, clean cuts. This guide will focus on how to efficiently execute pipe cutting, the appropriate type of tools that can be used to help with cutting, a few safe methods for cutting pipes without injury and a brief rundown on types of pipes you may need to cut through as well as simple strategies for making smooth and clean cuts resulting in better plumbing.

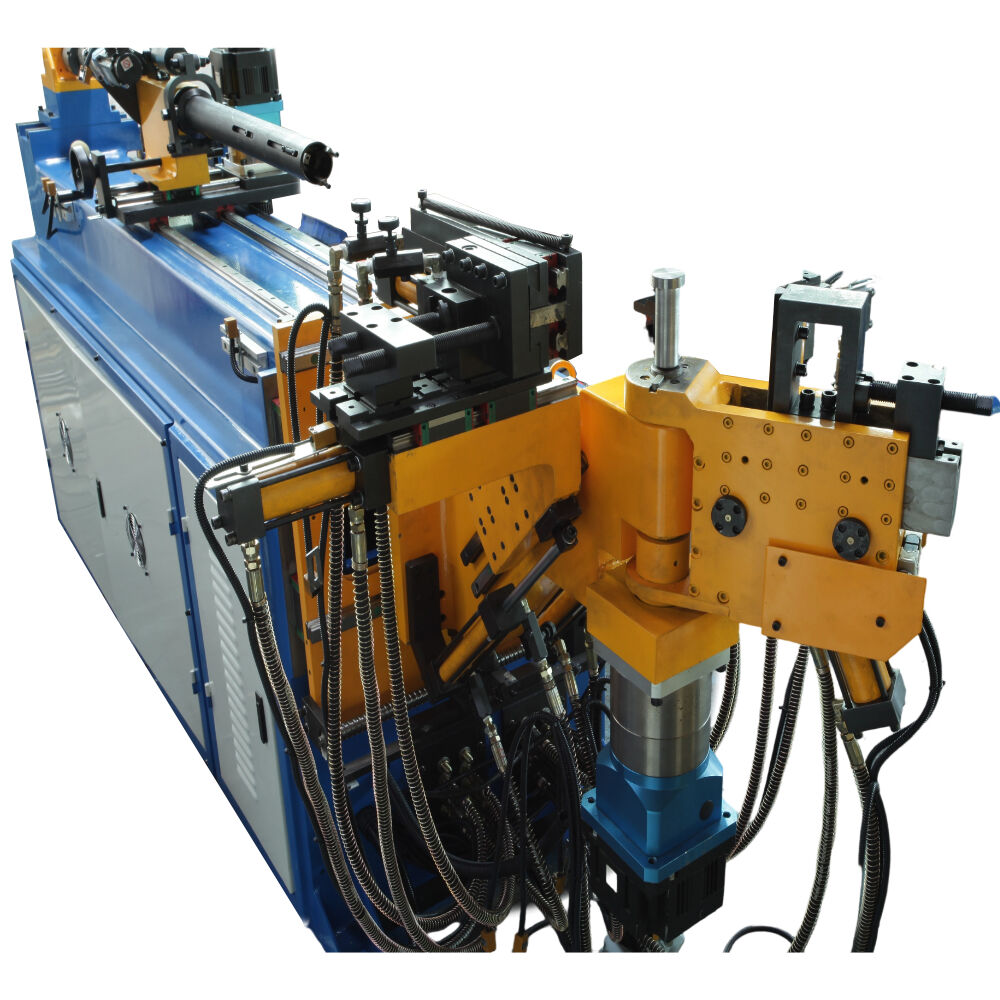

There are special tools available to trim pipes rapidly and accurately, along with Bao Rui's product pipe cutting machine. Types of Pipe CuttersOne common tool is called a pipe cutter. This tool is used to make the circular cut around the pipe and installs a neat, clean, high-speed operation without exerting too much physical strength. This is highly beneficial as it helps you to work quickly and effortlessly. Plasma cutting is another method of pipe cutting This way a super-hot beam of energy is applied to melt and cut metal pipes. Plasma cutting is fast and has a great accuracy and sharpness of the cuts, which is crucial for many professional construction projects.

Using some good cutting tools is important for a pipe fitting project. One of the greatest advantages of using these modern tools is their ability to cut pipes several times faster than traditional tools. You can then complete your work in less time. And they offer much higher precision in your cutting. Some of these devices have laser guides that will assist you to make accurate and square cuts. Having the appropriate tools can save you and prevent poor quality work.

It is very impotent to take care of safety measures while cutting pipes as it reduces the chances of accidents and injuries, just like the tube cutting machine supplied by Bao Rui. Six Things You Should Do To Stay Safe While Working With Pipes

Before you start cutting, ensure the pipe is held steadily and securely into position, same with Bao Rui's automatic pipe bending machine. This will save you from accidents and the cuts will be perfect.

Pipes can be commonly-made of metal, plastic or PVC, along with the pipe cutting machine developed by Bao Rui. Different tools and cutting methods for each type of pipe: For metal pipes, it is advised that you use plasma cutting or saws with a powerful carbide-tipped blades. They are effective in cutting through hardest of the material. A ratcheting cutter or hacksaw with a fine-toothed blade works best for plastic and PVC pipes. It is essential to use the proper tool for a given substance in order to perform accurate and clean cuts.

Clean cuts are very important when it comes to if your construction project will look great in the end, similar to the Bao Rui's product like stainless steel pipe bender machine. Make sure your cuts are clean to ensure the part fits properly. Tools such as pipe cutters and saws, that specifically designed for precise cutting can be used in order to make clean cuts. Always measure and mark the pipe before cutting to ensure your cuts are nice and accurate. When you are done making the cut, use a deburring tool or sandpaper to smooth off the edges. This can prevents sharp edges from causing problems later on.

Our company has Pipe cutting with high-quality production lines, as well as testing equipment, as well as the expertise of our engineers and designers. The company has been involved in the business since the beginning of time, specializing in the development of a wide range of CNC hydraulic pipe bender, pipe cutter aluminum cutter, chamfering machines, gear grinding machine and other products. We are able to provide you with various customized and personalized equipment to meet your specific requirements.

Establishing a regular product inspection procedure to ensure optimal operation and prolong the life of our Pipe cutting, and minimizing the time of failure.Focused on building long-term partnerships by providing tailored solutions that promote mutual growth and innovating with regard to laser lamp production.We're ISO9001 certified, CE certified and SGS certified. Prior to delivery, we check the machine, provide the user with a demonstration video or live streaming, and offer a one-year warranty. Our company's cutting-edge technology modern equipment, as well as scientific management have allowed it to remain flourishing in the highly competitive domestic and foreign markets. Our products are shipped to Europe, America, and Southeast Asia, and users have been very pleased with their purchase.

We provide a variety of Pipe cutting such as transportation by sea, on land and air transport. We offer a variety of options for trade transportation to make sure that the goods get to their final destination. Presently, we offer services to a variety of customers across the globe and export to more than 60 countries.

The products are widely used in Pipe cutting, kitchen hardware medical equipment, sports equipment, furniture, and in other pipe profile processing industry. We are experts in the industry of pipe and profile processing and your trusted partner. In these areas we use top-of-the-line technology to protect your needs