Hello friends! In this case we are going to learn how to cut copper tubing. You will see this type of tubing in many homes and buildings, being used for plumbing and heating. And we will help you how to do it yourself without needing to hire someone. That stainless tubing bender way you can save time and money! So let's get started with this #freebie fun project!

Copper Tubing Cutter – You need this tool to cut through the copper tubing. You can get this cutter from a hardware shop or if you like online as well. The Bao Rui bit is specially made to cut copper, and it cuts noticeably better than if you were to use another tool.

Step 3: Rotate the Cutter – Next, rotate the cutter around the copper tubing slow and steady. The Bao Rui cutter needs to be where the part of the tubing that you're trying keep is. These cnc tube bending trays are key to make sure you do not waste any copper.

Steady the Cutter — Be sure to keep the cutter steady as you cut into your food. Causing the cutter to “walk” or Bounce can prevent a precise cut and cause permanent damage as well. Concentrate on keeping your hands steady.

Apply the right pressure– Applying the Bao Rui apt amount of pressure while you are cutting is very crucial. If the end forming tube machine pressure is too low, the tubing will not be cut. Applying too much pressure can harm the tubing. Find a good balance!

Step TEN —- Debur Deburring Tool After cutting your copper tubing, you really should use a deburring tool. This stainless steel tube bending machine tool will remove any burrs and rounds over the edges of the cut opening. On this specific step being critically necessary, you want to ensure you are cut pipe is going to meet at about 100° as your fitting will be a compression fitting so that means tight fit so it does not leak.

Cutting Time — DO NOT rush While cutting! Besides it you may be in a hurry and could make errors or just damage the 1 2 tubing bender tubing. Give them time and concentrate on clean cuts every time. Recollect, practice makes a man perfect!

We Cut copper tubing a system of regular inspections of the product to ensure proper performance and extend the life of our light sources. This helps to reduce downtime.Laser lamp manufacturing is centered on establishing long-term relationships through providing customized solutions that encourage mutual growth and creativity.We're ISO9001 certified, CE certified and SGS certified. We test the equipment and provide a test video or live streaming prior to delivery and offer one year warranty. Our company's leading technology, top equipment, scientific management, and flawless service allow the company to maintain good development on the competitive domestic and international markets. Our products cover the entire country and been export into Europe, America and Southeast Asia countries. The products have been well-received by customers.

We offer a range of logistics options, including sea transport, Cut copper tubing and air transportation, among others. We offer a variety of options for transporting trade to ensure the goods reach their final destination. Presently, we offer services to a variety of customers all over the world and export our products to over 60 countries.

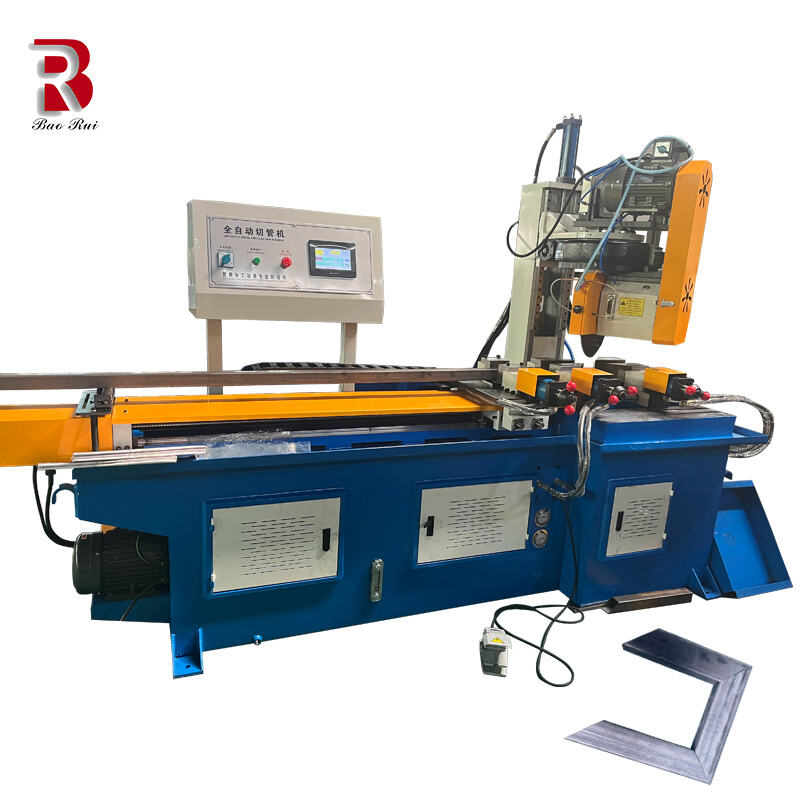

Our business is equipped with modern factories, advanced production machines, testing equipment and an experienced team of designers and technicians. The company has been involved in the field for 20 years, Cut copper tubing in the development of a full range of CNC hydraulic pipe bender, pipe cutter, aluminium cutter, chamfering machine, gear grinding machine and other products. We are able to provide you with various customized and personalized machines to meet your order requirements.

These products are used extensively in auto parts, Cut copper tubing, medical equipment, sports equipment, furniture and other pipe profiles processing industry. We are professional in the industry of pipe and profile processing and are your reliable partner. In these areas We offer the best technology to protect your needs