More and more leading companies (large manufacturers) in various industries are replacing traditional cutting equipment in batches, and pushing laser cutting machines to the core processing positions. This is not an accidental equipment upgrade, but an inevitable choice for the manufacturing industry to transform towards high precision, high efficiency and green manufacturing. Behind it are multiple considerations such as cost control, technology upgrading and market competition.

I. Precision Revolution: Solving the Core Pain Points of High-End Manufacturing

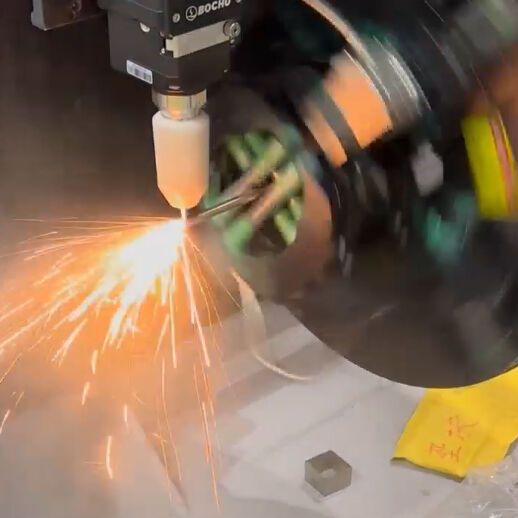

Major manufacturers favor laser cutting machines primarily due to their irreplaceable precision machining capabilities. Traditional die-cutting and flame cutting processes have long suffered from insufficient precision, large heat-affected zones, and material deformation. Laser cutting machines, using a high-energy-density laser beam as an "invisible tool," achieve a qualitative leap in processing precision—reaching a cutting accuracy of ±0.1mm, far superior to the ±0.5mm error range of traditional die-cutting. The cuts are fine and smooth, requiring almost no secondary grinding or trimming. This precision advantage perfectly aligns with the stringent requirements of major manufacturers in high-end manufacturing: in the automotive industry, laser-cut high-strength steel and aluminum alloy components contribute to lightweighting and structural safety improvements; in the aerospace field, the precision cutting of difficult-to-machine materials such as titanium alloys and high-temperature alloys directly impacts the performance and reliability of spacecraft; and in the electronics industry, only laser technology can achieve micron-level precision control for cutting micro-components such as circuit boards and sensors.

II. Cost Restructuring: Long-term Benefits Far Exceed Initial Investment

In terms of operating costs, laser cutting machines have a more prominent advantage. Highly automated laser equipment requires only one operator, reducing labor costs by more than 50% compared to traditional equipment; the material utilization rate is as high as 95% or more, far exceeding the 80%-90% level of traditional cutting. For example, a medium-sized factory that processes 100,000 products per year can save hundreds of thousands of yuan annually just on material savings.Meanwhile, the maintenance cost of laser cutting machines accounts for only 5%-10% of the initial investment, the equipment life is more than 10 years, and the investment payback period is usually only 1-3 years.

III. Technological Iteration: Adapting to the Diverse Needs of the Intelligent Manufacturing Era

The continuous upgrading of laser cutting technology has further amplified its appeal to major manufacturers. Today's laser cutting machines are no longer simple cutting tools, but intelligent manufacturing units that integrate AI intelligent control, automated loading and unloading, intelligent layout and other functions.