In high-end manufacturing sectors such as automotive parts, construction machinery, and aerospace, alloy steel, with its superior properties of high strength, high toughness, and corrosion resistance, has become the preferred material for core pipe fittings. However, the high hardness and toughness of alloy steel also bring many challenges to pipe cutting—traditional hot cutting easily leads to cut oxidation and coarse grains, while ordinary sawing suffers from rapid tool wear and insufficient precision. Cold sawing technology, with its unique process principle and adaptability, has gradually become the mainstream solution for alloy steel pipe processing, and even a standard feature in the production of high-precision automotive parts pipe fittings.

The core reason for choosing cold sawing to cut alloy steel pipes is that its cold-cutting process is compatible with the material characteristics of alloy steel, while also ensuring both processing quality and production efficiency. There are three main reasons for this:

1. No heat damage, ensuring material performance

The low temperature during cold sawing prevents oxidation, coarse grains, or thermal deformation of alloy steel cuts, thus avoiding impacts on subsequent welding, bending, and other processes. It is especially suitable for high-precision machining scenarios such as automotive parts.

2. Excellent cut quality, reducing secondary processes

Cold sawing produces a smooth, burr-free cut with high perpendicularity, requiring no additional grinding and allowing the material to proceed directly to the next processing step, significantly reducing process costs and time.

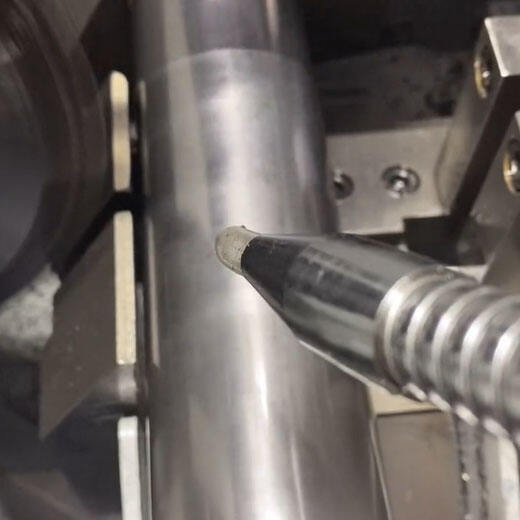

3. The blade is durable and suitable for high-hardness materials

Cold saws paired with carbide saw blades can handle the high hardness of alloy steel. The blade wear rate is much lower than that of tools such as grinding wheels, and the equipment is highly rigid, ensuring a stable and uninterrupted cutting process.