In the wave of intelligent manufacturing, laser tube cutting machines have grown from high-end niche equipment to a mainstay in the tube processing market.In the wave of the automotive industry's transformation towards new energy and lightweighting, laser tube cutting machines have leaped from auxiliary processing equipment to core production equipment.

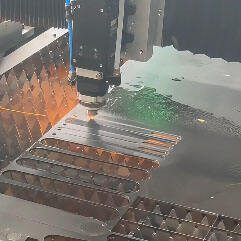

The core advantages of laser tube cutting machines are fully demonstrated in the processing of key automotive components. In vehicle body manufacturing, structural components such as anti-collision beams and frame longitudinal beams need to balance high strength and lightweight design. The full-stroke pneumatic chuck equipped with the laser can adaptively clamp tubes up to 240mm in diameter, precisely cutting materials such as stainless steel and aluminum alloys. The cuts are burr-free and require no secondary grinding, increasing production efficiency by 3 times compared to traditional equipment. Load-bearing components such as chassis steering tie rods and suspension arms are made of high-strength steel, and non-contact cutting technology reduces processing deformation, ensuring the stability of the components' mechanical properties.

In terms of production mode adaptation and cost control, laser tube cutting machines are a powerful tool for automakers to reduce costs and increase efficiency.

With its wide material adaptability and strong processing versatility, laser tube cutting machines have further broadened their application boundaries in automobile manufacturing. The materials used in automobile manufacturing are diverse, ranging from heat-resistant steel in the exhaust systems of traditional gasoline vehicles to lightweight aluminum and titanium alloys in the bodies and battery frames of new energy vehicles. Laser tube cutting machines can efficiently cut all of these materials without requiring changes to core equipment for different materials. Furthermore, they can perform various processing steps such as straight cutting, beveling, irregular cutting, and drilling, meeting both the standardized processing needs of traditional automotive structural components and the personalized processing requirements of irregularly shaped parts in new energy vehicles, breaking the limitations of traditional tube cutting equipment that is "single-process, single-material."

Compared to traditional tube cutting equipment, laser tube cutting machines offer advantages such as energy saving, environmental protection, and long-term cost control. The processing generates no dust or noise pollution, aligning with the global trend towards green and low-carbon manufacturing. Furthermore, their high processing precision and material utilization reduce tube waste, and their low failure rate and ease of maintenance effectively lower overall production costs for automakers in the long run, making them a crucial choice for global automakers to reduce costs, increase efficiency, and achieve green production.

The combination of these core advantages has enabled laser tube cutting machines to break through regional and industry limitations. From high-end manufacturing for European luxury car companies to large-scale production for Asian new energy vehicle companies, and to the automotive industry layout in emerging global markets, they have become an indispensable core processing equipment, continuously leading the global automotive tube processing towards high precision, high efficiency, intelligence, and green development.