Customized tube shrinking machines differ from standard assembly line equipment. Their core production characteristics can be summarized as being customized to order, technology-intensive, and with services covering the entire process.

1. Order-driven, with strong non-standard attributes: Each piece of equipment is designed to match the customer's pipe parameters, pipe shrinking process, and cycle time requirements. There is no unified production template. Process routes and tooling fixtures need to be planned and customized according to needs.

2. Design First, Determining Production Success or Failure. Production begins with communication of technical solutions, which requires finalizing the tube shrinking accuracy, structural layout, and system configuration. Simulation analysis should be conducted when necessary, as design deviations will directly lead to rework in subsequent processing and assembly.

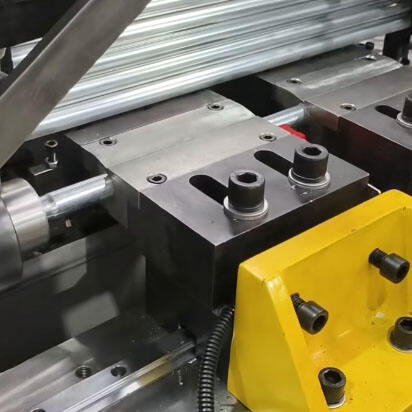

3. Precision machining and stringent process requirements: Key components such as the machine body, mold, and mandrel require high-precision machining, relying on CNC equipment and strict testing. The selection of materials also needs to match the requirements of high strength and high wear resistance in working conditions.

4. Debugging is crucial and tests professional skills. After assembly, the hydraulic, servo systems and mold parameters need to be repeatedly debugged to verify the shrinking accuracy and stability. The debugging cycle often accounts for a significant proportion of the production time.

5. Service loop, solutions go beyond equipment. Production goes beyond equipment delivery, encompassing pre-production process assessment, mid-production installation and training, and post-production maintenance and upgrades. Essentially, it provides customers with a comprehensive solution for pipe fitting processing.