There is a great company called Bao Rui which specializes in manufacturing pipe and tube bypassing machines. There is a variety of equipment that is used for different jobs and servicing of projects, these machines are very important as they are used to shape pipes and tubes. You may believe that bending pipes is a simple job, but you will definitely need extensive experience and pay close attention to details to do this correctly. Let us delve into pipe and tube bending, and why it is important to do this process accurately.

It has been a common practice for a very long time. Pipe bending was first utilized by the Egyptians to form decorative pieces a long time ago, and then by the Romans who used this technique to build systems to transport water known as aqueducts. Pipe and tube bending has been used in a wide range of industries such as construction, oil and gas, and automotive manufacturing.

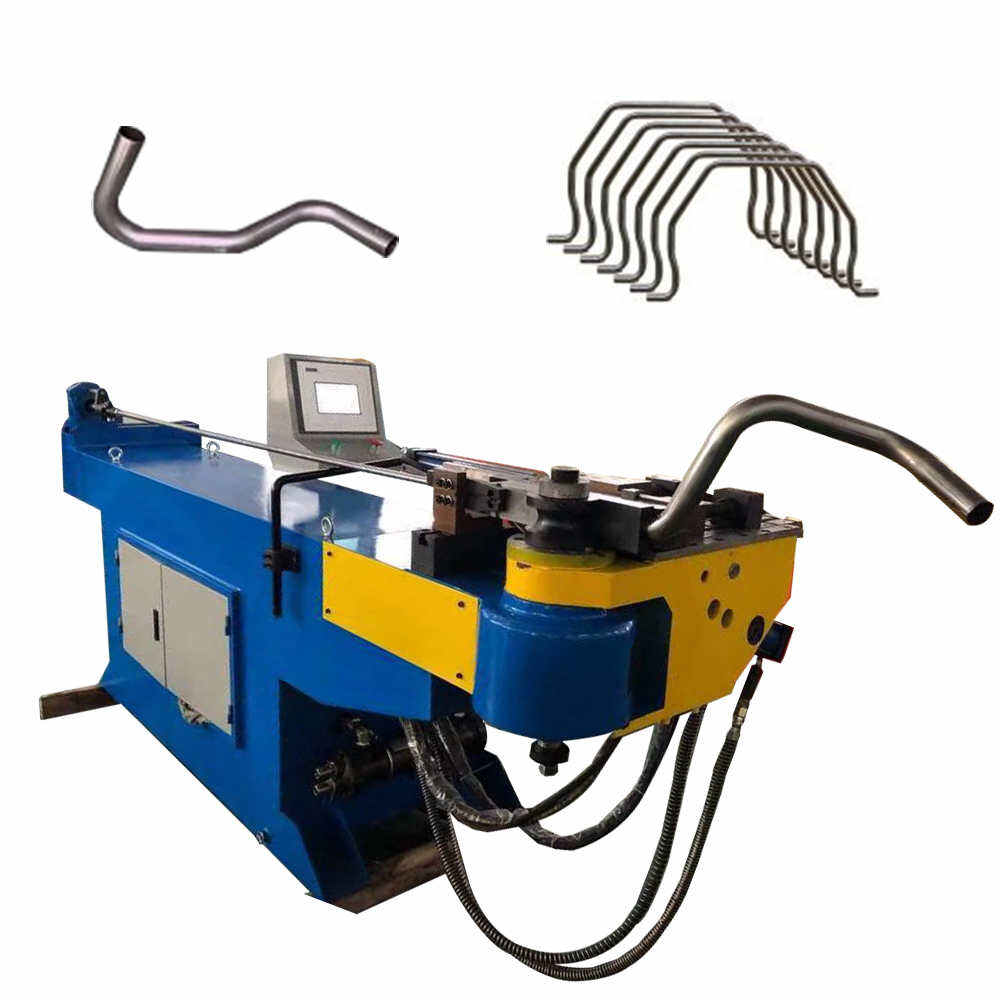

Pipe and tube bending[B161] is the process of producing a bend in a pipe or tube. This is achieved through specific machines that exert pressure through rollers to form the pipe into the desired shape. The operator must know about the material, the properties of the pipe, what angle/curve is required etc. That knowledge is critical for the bend to be performed exactly so that the tubing will behave the way its meant to in whatever specific application it is to be used in.

Bao Rui: In this article, we will explore the advantages of using different types of bending machines. This allows us to standardize each bend for consistent quality and accuracy. Therefore every time you order from our machines we guarantee a great product. Consistency is key for industries that need pipes and tubes to operate smoothly.

Pipe and tube bending is an area where precision is paramount. Any error — even if it is one of the smallest degree and would not statistically vary from other identical shapes — becomes a potential manufacturer of problems for the resulting object. That is particularly pertinent in industries like aerospace and automotive manufacturing, where safety is of the utmost importance and even small mistakes can cause severe problems.

We are using the cutting-edge technologies for precise bending process, which is incorporated in the design of Bao Rui machines. They conduct real-time angle measurement process monitoring, for instance. These capabilities keep every bend precise and aligned with the required specifications, which is paramount to the quality of the finished product.

We use advanced software which enables our operators to program and control the bending process on our machines. Not only does this make the manufacturing process itself faster and more efficient, it also helps limit the risk of human error. Reducing mistakes means that we will always have accurate results and of the levels our clients expect.

We pipe and tube bending machine a variety of logistical routes, which include air and land as well as sea transportation. We offer a wide range of options for transporting trade to ensure that the products are exported to the destination. We currently provide services to a variety of clients across the globe and export to more than 60 countries.

We use a pipe and tube bending machine of regular inspections of products to ensure that the light source is performing at its best and prolong the life span of our lighting sources. This will minimize time to repair.We are focused on establishing long-term relationships by providing tailored solutions that enable mutual growth and innovation for laser lamp manufacturing.We have achieved ISO9001 Quality System Certification, CE certification and SGS certification. We test the machine and provide test video or live streaming prior to delivery and provide a one-year warranty. Our company's leading technology, modern equipment, innovative management and perfect service enable the enterprise to keep its development on track within the highly competitive domestic and international markets. All products have covered the entire country and been export to Europe, America and Southeast Asia countries. They have been well-received by customers.

pipe and tube bending machine products are extensively used in kitchen hardware, medical equipment, sports equipment furniture and other pipe profiles processing industry. We are experts in the industry of pipe and profile processing and your trusted partner. In these areas We offer the best technology to ensure your safety.

Our factory is modern and has premises and professional production lines and pipe and tube bending machine, along with the expertise of our technical and design engineers. Our company has been engaged in the industry for over 20 years, and specializes in the production of a wide range of CNC hydraulic pipe bender, pipe cutter, aluminum cutter, chamfering device, grinding gears and other products. We can supply you with several customized and individualized machines to meet your ordering needs