Many jobs and industries are being revolutionized by technology. It is speeding up all the processes, makes them error free and cheaper! Automated pipe bending Another key technology that is helping industrial units. The Best of Both Worlds with Automated Pipe Benders — Taylor Machine Works This is disrupting many industries and enabling businesses to operate smarter, better, faster in a multitude of areas.

Newer automated pipe bending machines bend pipes much more quickly, with far great precision and at a lower cost than they would be made by hand. Over the years, the old backs of bending pipes by hand or using simple machines took many hours of labour. This can be extremely exhausting and time-consuming. Until now, things were done manually and automation machinery is created to cut the plastic much faster and accurately than one can do himself.

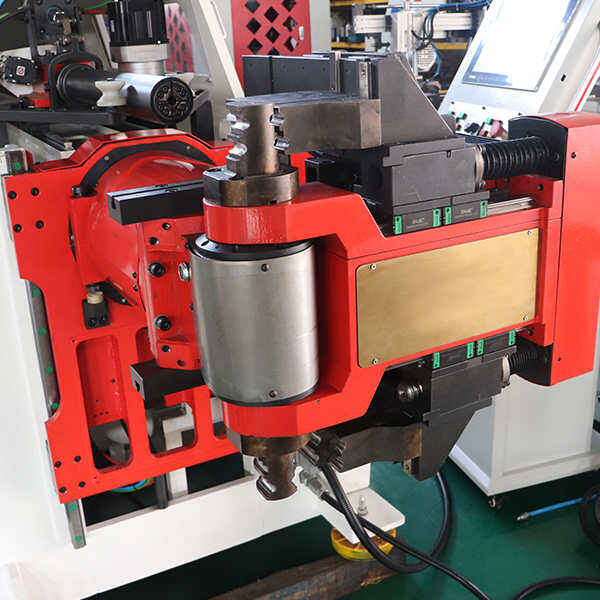

The latest smart technology is applied to stainless steel pipe bender machines, relying on the machine to bend metal pipes with close-to-zero error rate and in exactly the right angle. In these machines, certain types of commands are much easier to process, ultimately allowing them to create the right forms. It can even bend pipes in the form of spirals and coils which were nearly impossible to build earlier. This allows businesses to design products that are more complex and interesting, addressing the broader needs of their customer base.

Pipe Bending Machine can also save businesses Money in Long Run by saving the overhead cost of manually hiring workers to bending it. This is significant since bringing aboard more people costs money. And these babies really do produce a consistent high quality product, meaning they break down less often due to post facto mistakes. Making products in the right way at first ensures businesses do not get negative feedback.

The world of industries have been highly impacted by automated pipe bending machines. They are used by car companies to forge critical components — such as exhaust systems and fuel lines. These are essential for the cars to function properly and safely. Plumbing companies also use computer-controlled pipe bending to make any pipes necessary for construction work. This technology is what enables them to create the correct piping as quickly and as accurately for a job-site.

Automated pipe bending in the medical industry is key to bending pipes used as component for medical devices. These components should be manufactured precisely ensuring their functioning in the right manner and safe usage for patients. The air industry also utilizes automatic pipe benders, as aeronautic interest in the precision of bending pipes. Aircraft is full of pipes and these air bending machines can be used to produce pneumatic lines, hydraulic lines, fuel lines and exhaust systems that are safe and reliable.

Automated pipe benders can also be used in corporations to produce specialty pipes for their products. This means they can create some of the most original and inventive designs on the market. This works for us because those unique something special brands are what gives that competitive edge to businesses over the other players in their industry. It provides greater potential for innovation and the power to gain new customers.

We provide a variety of logistic routes, including automated pipe bender or land transport. We offer a range of solutions for the transport of trade to ensure the goods reach their destination. We currently provide services for many customers around the world. We also export our products to over 60 countries.

Our business is equipped with modern factories, advanced production machines, testing equipment and an experienced team of designers and technicians. The company has been involved in the field for 20 years, automated pipe bender in the development of a full range of CNC hydraulic pipe bender, pipe cutter, aluminium cutter, chamfering machine, gear grinding machine and other products. We are able to provide you with various customized and personalized machines to meet your order requirements.

Establishing a regular product inspection method to ensure that the operation is optimal and prolong the automated pipe bender of our light sources, and minimizing the amount of downtime.Laser lamp manufacturing focuses on establishing long-term partnerships by providing customized solutions that encourage mutual growth and innovation.We are ISO9001 certified, CE certified and SGS certified. We test the machine and provide test video or live streaming prior to delivery and offer one year warranty. Our company's top technology, advanced equipment, innovative management and impeccable service allows the company to maintain good development within the highly competitive domestic and international markets. Our products are shipped to Europe, America, and Southeast Asia, and users have been very pleased with their purchase.

The automated pipe bender are extensively used in kitchen hardware, medical equipment, sports equipment, furniture and other pipe profiles processing industry. We are professional in the process of processing pipes and profiles and are your reliable partner. In these areas we offer top-of-the-line technology to ensure your safety.